GRP (Glasfiber Reinforced Plastics) Spinner project.

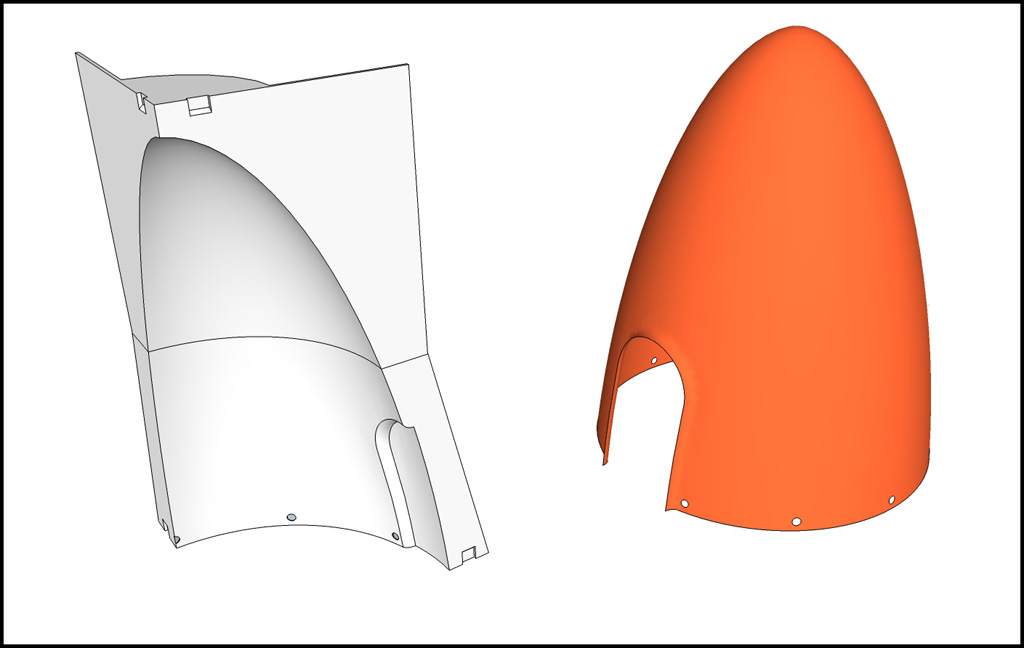

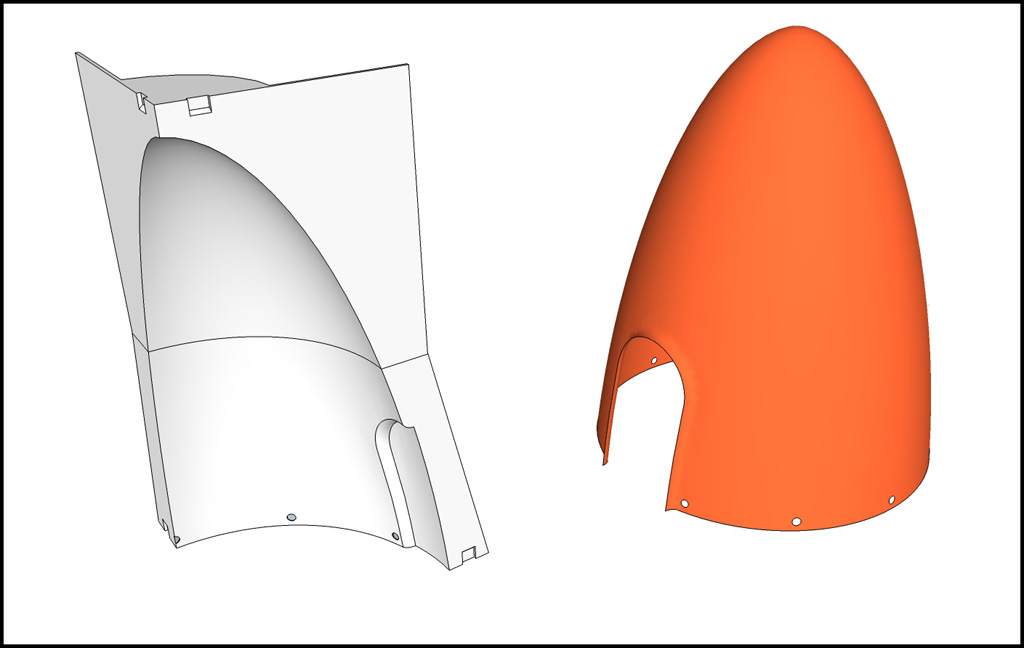

Step 1: CAD design of the spinner and the mold.

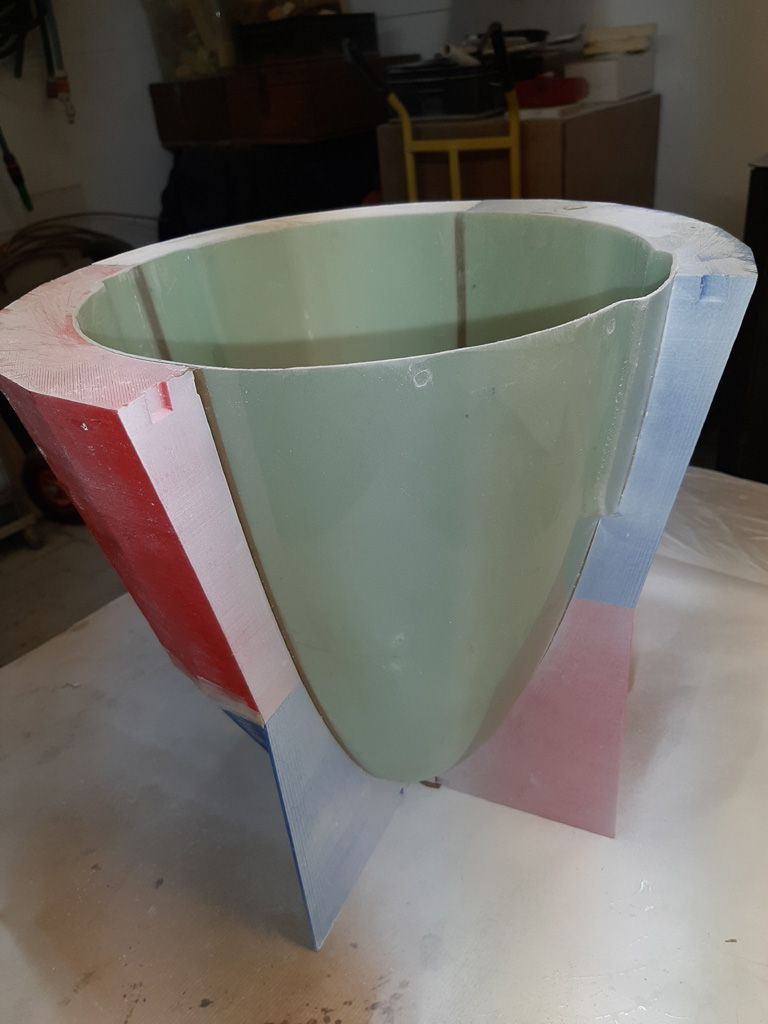

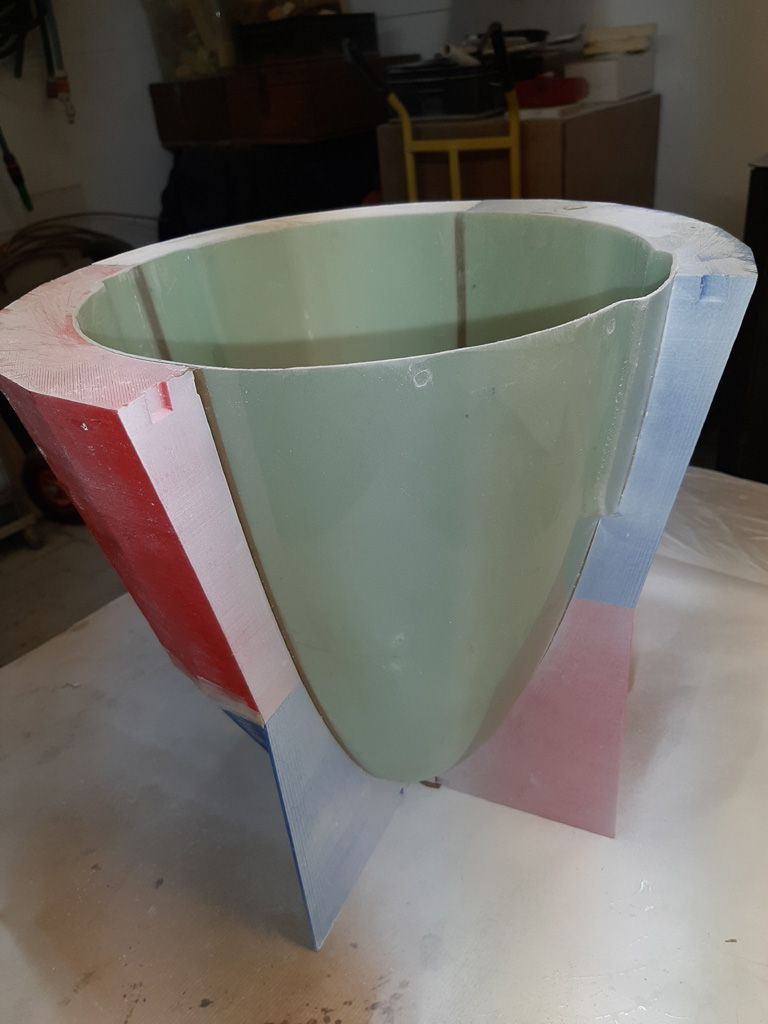

Step 2: 3D-printed mold.

Surface is prepaired with filler and smoothed with PU lacquer.

Step 3: Laminating 8 layers of bidirectional glasfiber with epoxy resin.

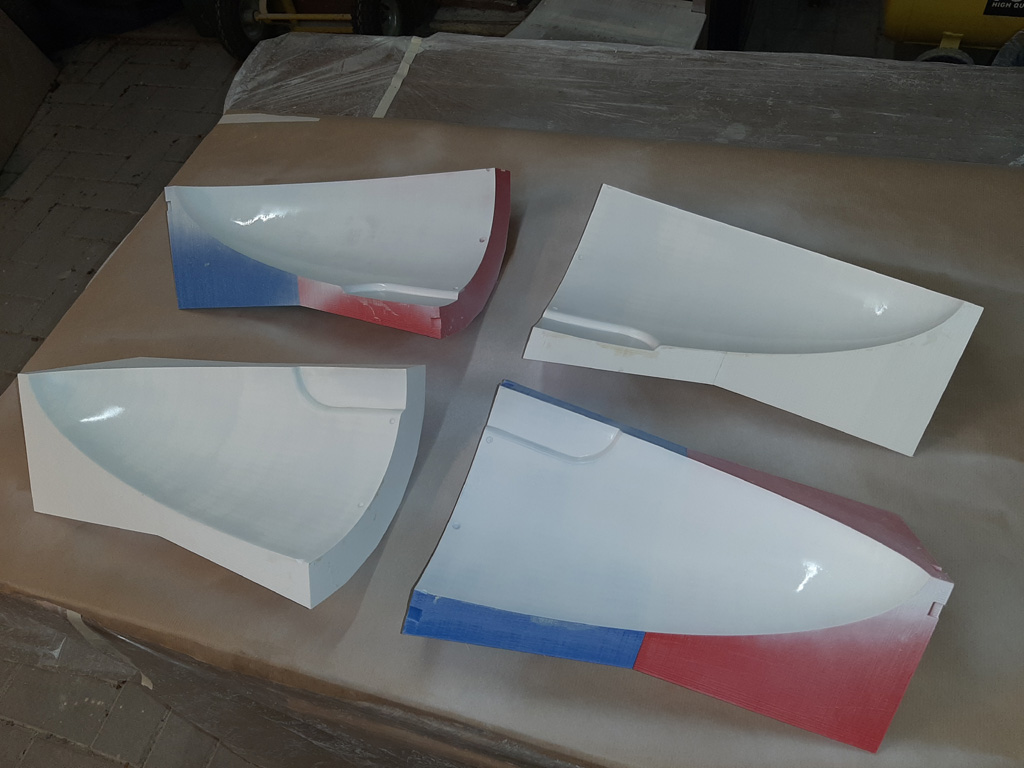

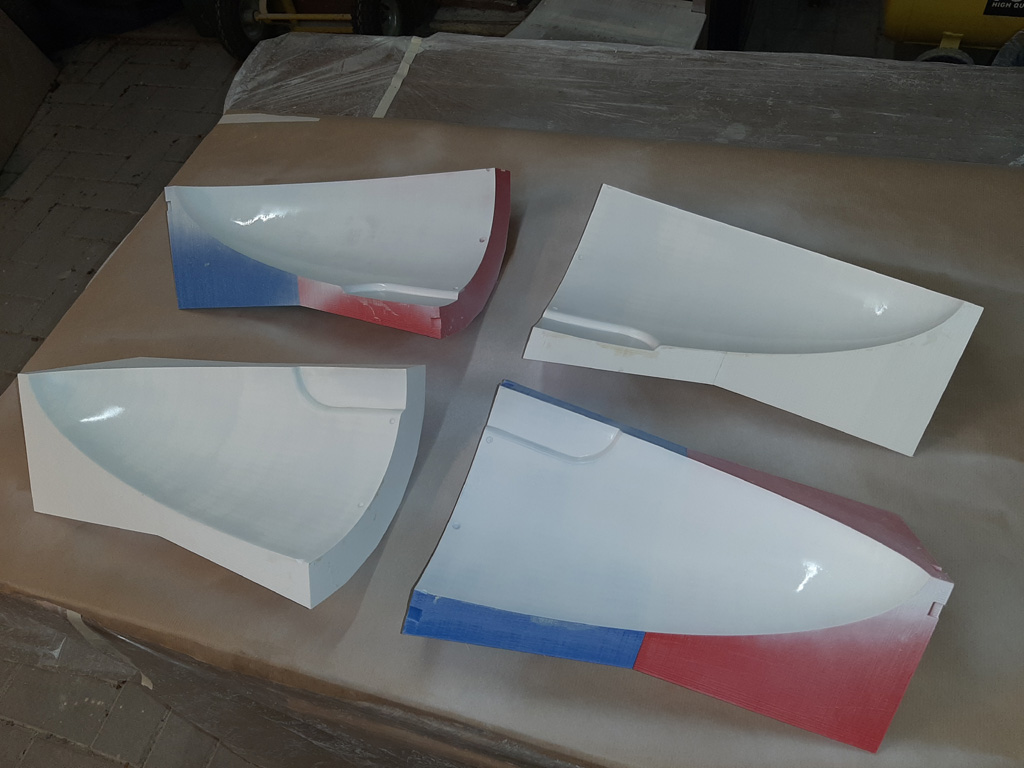

Step 4: 18 hours later opening the mold is an exiting moment!

Step 5: Demolding

Step 6: Tempering 15 hours at 60°C

Step 7: Painting with 2K filler / grounding.

Step 8: Final painting with 2K PU Lacquer.